This article is dedicated to those who want to learn more about the raw materials to make mobile phone stickers. If you have any question you could leave a massage below, we will get back to you soon.

For those various custom cellphone stickers you have ever seen, what the raw materials of the custom cellphone stickers are? Here I answer this question with the example of the custom cellphone stickers produced by Daqin 3D mobile skin designing and making system. They are all made of vinyl materials. Such materials are environmental protection and harmless to humans.

The materials are divided into 3 types: the printing design film, laminating film and the cutting films.

The printing design films and the laminating films work together. Once the printing design film is well-printed, it will need to be laminated in order to become waterproof and anti-scratch. Also the laminating effect film have 8 effects to choose from, such as the effect of glossy, matte, flash-matte, ice flower, twill, gridding, leather and 3D water drops.

1. Printing design films

There are 5 different kinds of printing design films from Daqin.The 3M white printing film is with the best quality. It’s with blowholes on the sticky side, which can avoid bubbling while applying it to the mobile phone. The price of it is comparatively high, but surely it worth such price.

The Ordinary white printing film is with normal quality. It doesn’t have blowholes on the sticky side; so that there may be some bubbles occur. However, since the price is of it is comparatively cheap, it also very popular.

The Ordinary white printing films have another version, which have blowhole. Due to the blowhole, it’s with comparatively expensive price of the one without blowhole.

The silver glittering film is with silver glittering effect. It’s also doesn’t have blowholes on the sticky side; in the same theory, if it isn’t applied correctly, there may be some bubbles occur.

The transparent printing film is a layer of transparent film. It’s without the blowholes on the sticky side. Its quality is the same with the ordinary white printing film, with same price.

2. Laminating effect films

Laminating effect film is a layer of films that laminate on the top surface of the well-cut printing design film, with the purpose of make it waterproof and anti-scratch, as well as adding certain effect for decoration. After laminating with a specific kind of laminating effect film, it will looks and feels even more personalized.

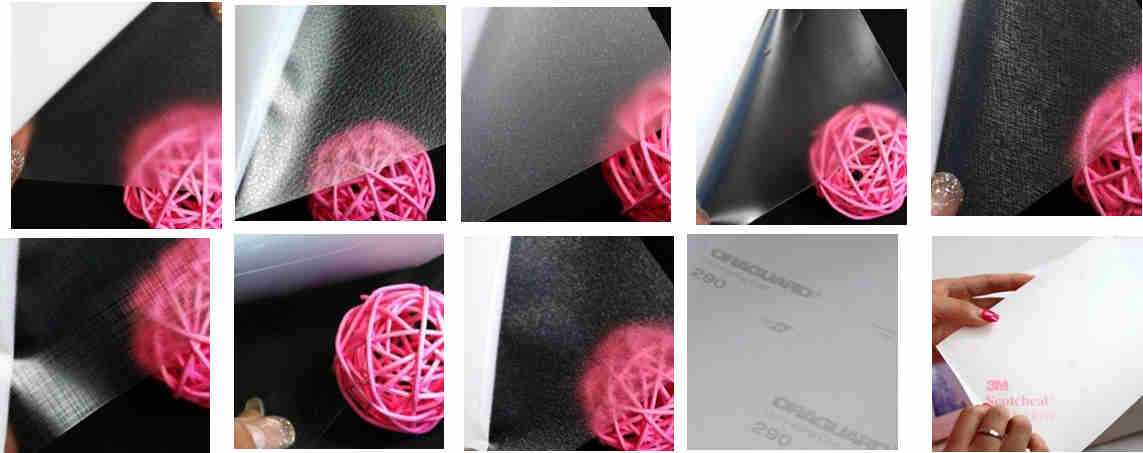

The laminating effect film have 8 effects to choose from, such as the effect of glossy, matte, flash-matte, ice flower, twill, gridding, leather and 3D water drops.

In the next article I will introduce the cutting films materials.

Leave a Reply